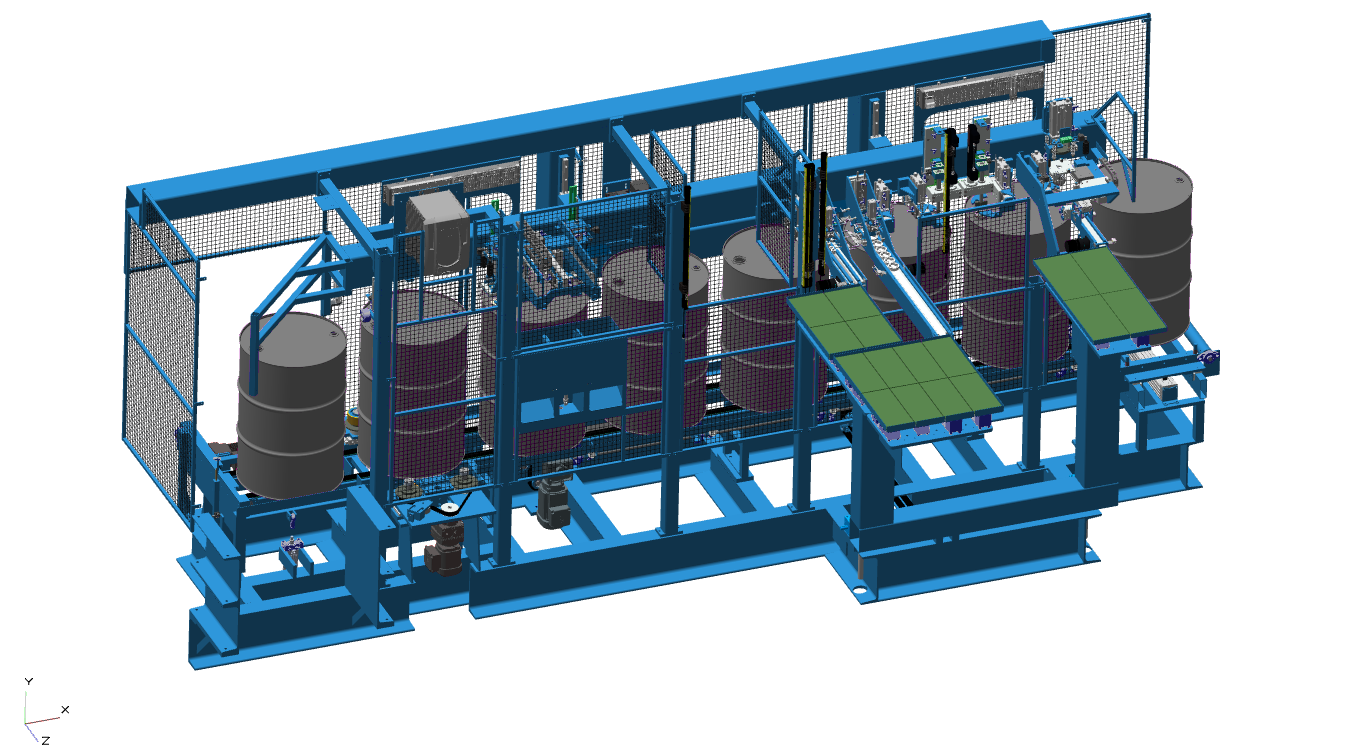

End Of Line / Bung Screwing

This machine is designed for removing paint caps, feeding and tightening 2″ and 3/4″ Tri-sure plugs and applying the 3/4″ cap seals. The drums are orientated for optimal positioning. The entrance load station contains a height measurement to adapt the complete machine to the requested height.

Feeding is done by a vibrating bowl with a capacity of approximately 300 plugs. A pick and place unit with gripper places the plug on the bung hole. The plugs are screwed at the required torque with a Desoutter electric motor with torque control. The Desoutter program checks the tightening based on the torque related to the expected rotations to eliminate badly tightened plugs. All tightening programs for different type of plugs can be stored in the recipes on the HMI.

The exit conveyor has an automatic lateral rejection conveyor for the drums where one of the plugs has not been properly screwed. The operator can correct the drums manually and easily shift the drums back in to the production line.

Each of the above stations can be enabled or disabled according to the production order.